A Novel Adjustable Breast Oncoplastic Surgery Simulator (ABOSS) Markup Model

________________________________________

Problem Statement

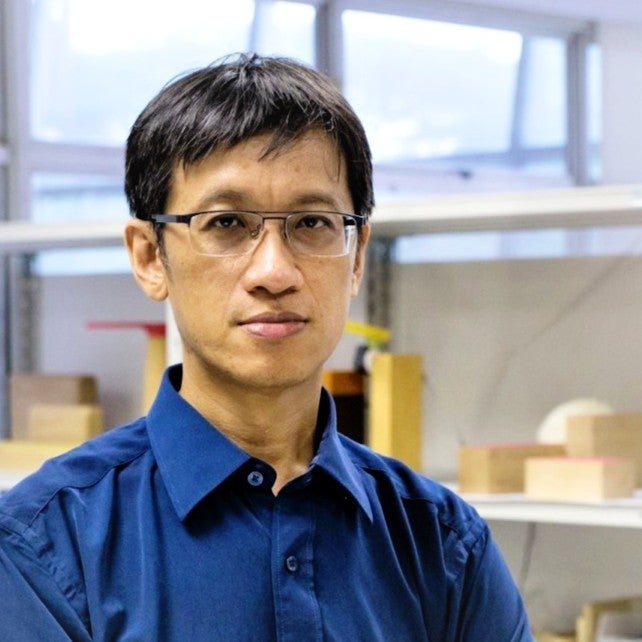

Currently, female human volunteers are used in mark-up lessons that require the learner to manoeuvre the breast to perform the mark-up. As volunteers will have to undress in front of a group of learners and allow markings to be drawn on their breasts, it is hard to recruit volunteers. Breast models have been developed to teach mark-up. However, each model is expensive and not reusable. The models can only be used for the practice of certain techniques pertaining to select breast sizes, since the breast shape and size of each model is fixed. However, in reality, different techniques are used for each breast size. Hence, having an easily adjustable and cost-effective breast teaching model enables the practice of various techniques catered to different breast sizes.

Objective

The primary project objective is to develop a novel Adjustable Breast Oncoplastic Surgery Simulator (ABOSS) mark-up model via 3D scanning, 3D modelling, and 3D printing. The ABOSS model is a surgical training tool for mark-up purposes, leading to safer operations. The benefits of this model over current existing teaching models are:

- It allows variations in the breast volume to permit the teaching of various techniques catered to different breast sizes

- It eliminates the logistic issues of recruiting volunteers of different breast sizes and is more cost effective compared to the current single use breast models

- It allows the practice of various techniques repeatedly and for prolonged sessions.

Key Benefits/ Outcomes

A novel Adjustable Breast Oncoplastic Surgery Simulator (ABOSS) mark-up model was successfully created. The breast model can accommodate three broad categories of ptosis. The size can be adjusted by the volume of slime added within the hollowed-out breast model shown.

This project also showcased the ability of 3D printing using a mould to shorten the entire product development cycle. 3D printing enables quick iteration on a mould that involves complex geometries such as breast shape. Custom mould enables designers to surface possible issues before production and gives designers the option to optimise the product for production process.

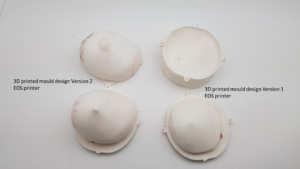

Breast moulds created from 3D Scanned data.

3D printed breast with J750 and Connex3 and silicone casted with different density using 3D printed moulds.

Customised slime for fluidity to mimic breast mass when being moved around for marking.