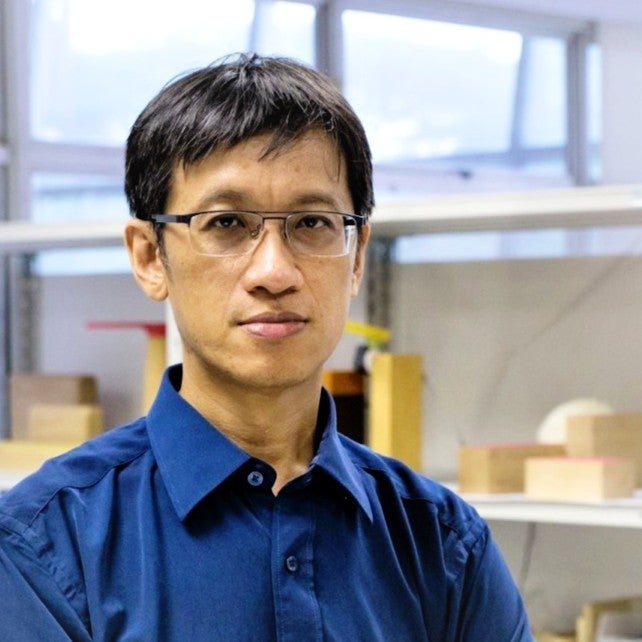

3D Printing Assisted Surgery and Custom Prosthesis for Saving a Great Pied Hornbill

________________________________________

Problem Statement

A great hornbill in Jurong Bird Park was diagnosed with cancer in its casque. Surgery was required to remove the cancer tissue, which involved the removal of a large portion of the bird’s casque. As survival of the hornbill is unlikely with a significant loss of its casque, an artificial one is required to ensure the bird can live post-surgery.

Wildlife Reserves Singapore (WRS) approached NUS to help explore options to save this bird by using 3D printing to develop a surgical guide to correctly remove the diseased tissue and a prosthesis to protect the wound during healing.

Objective

The primary project objective is to create an artificial casque that ensures the hornbill’s continued survival. The prosthesis must also be ergonomic and satisfactory such that the bird will not reject the prosthesis.

Key Benefits/ Outcomes

The surgical guide and prosthesis were successfully designed by the team from Keio-NUS cute centre using CT scans of the hornbill and manufactured at AM.NUS. Nylon was chosen as the material of choice as it is lightweight and biocompatible.

On September 13, 2018, the hornbill underwent surgery to fit the artificial casque. The surgery was a great success, and the bird was eating normally the day after surgery, gradually exhibiting natural behaviour during the recovery process. He has also adapted well to the implant as he coloured the white prosthesis yellow with a dye from his feathers during preening. This indicated that the hornbill had accepted the prosthesis as part of him.

https://news.nus.edu.sg/hornbill-gets-new-lease-of-life-with-prosthesis/

https://www.treehugger.com/hornbill-gets-second-chance-d-printed-prosthetic-4859829

A normal great pied hornbill (left). The infected casque of great pied hornbill in JBP (right).

The surgery was successfully performed. Surgical guide (middle) and prosthesis (right) were designed based on CT data and fabricated at AM.NUS.

Within 8 weeks of the surgery, the bird was back in the exhibition area.