3DP Process Certification of Cabin Interior Part for Aviation Industry

________________________________________

Problem Statement

ST Engineering’s Aerospace sector, being at the forefront of the Maintenance, Repair, and Overhaul (MRO) business, recognizes the tremendous potential that Additive Manufacturing (AM) holds for MRO. Leveraging AM improves supply chain resilience and decreases turn-around time, providing value to our customers and further strengthening ST Engineering’s position as an MRO leader. However, the lack of existing standards to guide the AM processes creates a challenge to establish and qualify the AM processes needed to make parts for certification and then installed on aircraft.

Objective

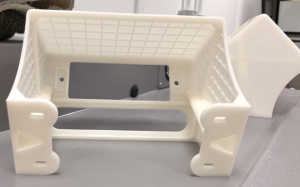

This project aims to develop and establish the process for Selective Laser Sintering (SLS) technology using flame-retardant PA2241FR material based on combined knowledge from both NUS and ST Engineering, focusing on demonstrating the reliability and consistency of the AM process through collaborative R&D approach, as the first in its kind in this region. In parallel with this collaboration with AM.NUS, ST Engineering launches its in-house project to certify a cabin interior part, manufactured through this qualified SLS process.

Demonstrator printed using EOS P396

Key Benefits/Outcomes

- ST Engineering is certified to design and produce selected parts by AM, having obtained the first EASA (European Union Aviation Safety Agency) STC (Supplemental Type Certificate) in the region.

- The SLS manufacturing process consists of end-to-end process definition using PA2241FR material and the EOS P396 printer has been qualified to make parts for aviation application.

AM can be used to manufacture complex geometry aviation parts at lower weight and faster turn-around-time. This could improve supply chain resilience and translates into fuel savings and lower emissions.