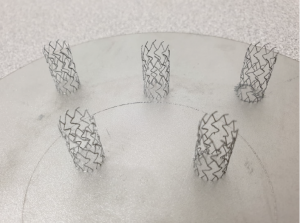

3D Printing of Nitinol (NiTi) Stents for Medical Applications

________________________________________

Problem Statement

The market demand for Nitinol (NiTi) stents is increasing dramatically due to the rise of cardiovascular disease and peripheral vascular disease (PVD). However, processing and machining Nitinol is a difficult task. Laser cutting and braiding are common methods of fabricating Nitinol stents, but stent designs are limited by the traditional production methods. Thus, this calls for a need to develop new stent designs and methods of fabrication for superelastic Nitinol.

Objective

An adventure of 3D printing of Nitinol stent started in 2018 under a collaborative project between AM.NUS and Interplex Precision Technology (Singapore) Pte Ltd. This project aims to design and develop superior Nitinol stents using SLM technology that could meet medical requirements. The relationship between the 3D printing process (including powder preparation and post-process heat treatment) and Nitinol properties/microstructures are also being investigated.

Outcomes/Benefits

- Super elastic (shape memory effect) Nitinol stents through novel designs manufacturable by 3D printing (i.e. SLM), one of the world’s earliest inventions in the medical field.

- Patent filed based on 3D printable designs, optimal SLM parameter setting, and controllable methods on how to produce 3D printable Nitinol stents with required mechanical properties and phase transformations. Eventually, it will be licensed and commercialized by Interplex’s Medical Business.

- The relation of process-microstructure-property of 3D printed Nitinol stent was established, which can be used to customize the functional and mechanical properties of stents when applied to specific patients. Three key milestones were achieved:

- Established the process-structure-property relation of Nitinol stent fabricated via Selective Laser Melting (SLM) with optimized printing parameters,

- Developed design for additive manufacturing (DfAM) guidelines for 3D printable Nitinol stents